The evolution of the college campus is alive and well. The days of hanging out in your dorm room with friends are over. Today’s students demand a different type of learning environment that celebrates and supports large group interaction and open collaboration. Common areas and gathering spaces for learning are in high demand. The areas must be designed to meet today’s needs but also be adaptable for future needs.

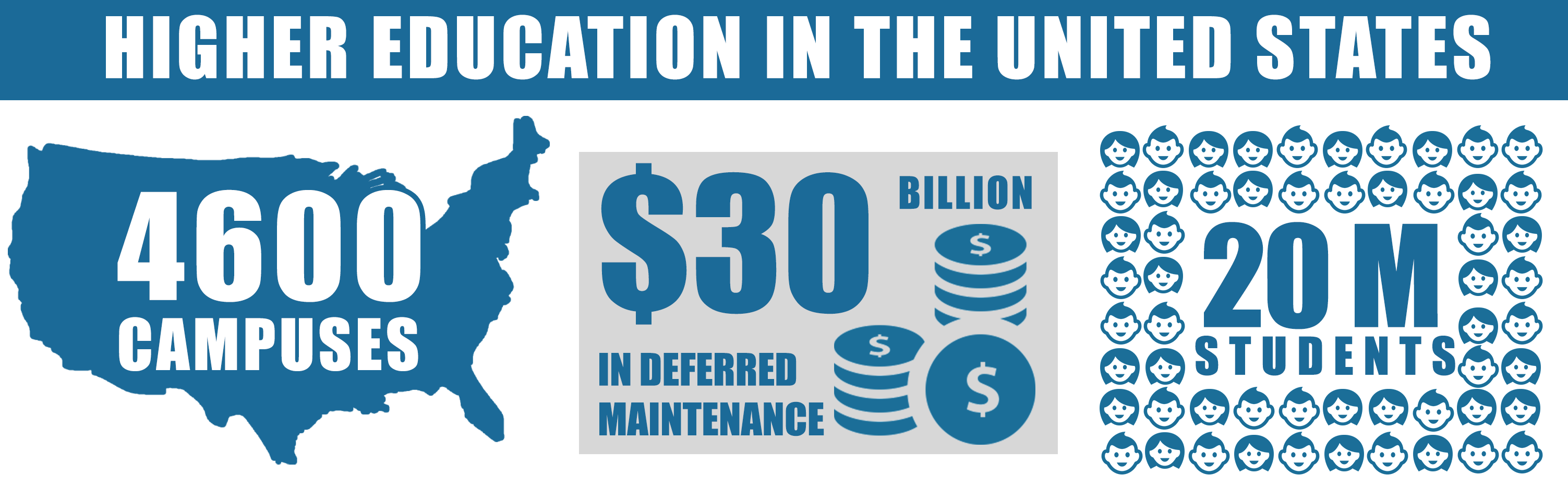

Most colleges and universities are large, sprawling campuses with many buildings and structures, therefore improvements happen in a piecemeal fashion. In 2015, there were over 4,600 campuses across the US alone. Maintenance on those campuses takes an enormous amount of money and has resulted in over $30 billion dollars in “deferred maintenance” projects. This means the problem is there, but the money to fix it isn’t so it must wait. Coupled with the fact that in 2019, there were 19.9 million students enrolled in higher education according to the National Center for Education Statistics and you have a situation where the structures on campuses continue to take a beating and repair dollars have to be spent as responsibly as possible.

Trending now are construction projects on campus that aim to modernize and celebrate the evolution of learning with open, collaborative spaces. New buildings are being designed to both blend with historic structures and stand out as contemporary “works of art”. Precast concrete products are major players in both new construction and the renovation of decades old structures for the many attributes they possess.

Precast concrete products offer:

Energy efficiency: concrete is a top thermally efficient building product

Resilient design: Protects against natural and man made events.

Aesthetic beauty and architectural interest: manufactured to match the historic quality of existing buildings

Speedy installation: Works well in tight schedules to minimize disruptions on campus. Not hindered by weather and uses minimal labor personnel.

Safety and health conscious attributes: great for fire containment and mold/mildew resistance.

Incredible lifespan with minimal maintenance costs: 100 year in most cases

Noise cancelling: cuts down on vibration and noise transfer

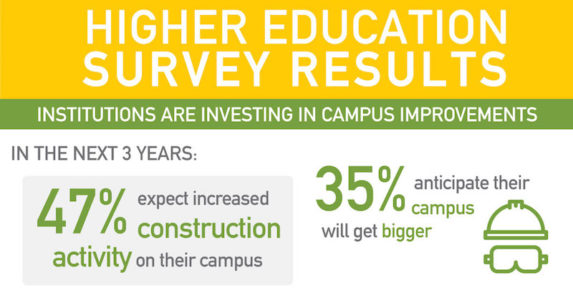

Colleges recognize that to attract new students, they need to invest in their facilities. According to recent studies, 47% of schools expect to increase construction on their campuses in the next 3 years with common spaces and collaborative areas topping the list of project types, along with increased housing and parking.

Graphics via Facility Executive

How does precast concrete meet the needs of colleges and universities?

Through the creation of spaces that are safe, well-designed and environmentally friendly, students are enjoying the transition from the old, stuffy classroom of the past to an open, engaging and supportive learning environment that reflects the learning style of today. Visit www.pcine.org and click on the Higher Education tab to access design resources ranging from building enclosure designs to sustainable design and storm resistance. Also available on the website are recent publications highlighting university projects of various scopes and sizes, some of which are highlighted below.

Pendleton West Classroom at Wellesley College found themselves with an outdated and unsafe structure and turned to precast concrete to rectify the situation. Through the use of specialty molds, the concrete panels were manufactured with a wood grain appearance and erected into a LEED certifiable classroom/lecture hall space with a contemporary flair in only three weeks utilizing just one crane.

Learn More

Suffolk University Classroom project was designed with a distinctive appearance that garners attention but also blends nicely with existing structures. The 3-D effect on the facade, as well as geometric shapes, slopes and ribbing throughout the structure is visually appealing and adds interest. The project made the most of funding by erecting panels during the second shift when the crane being used for other purposes on the site was finished for the day by the first shift.

Learn More

University of New Haven Westside Residence Hall filled the growing need for student housing while also creating open pods and lounge areas for socializing and collaborative learning. Design challenges ate up time at the onset of the project and required a fast-track schedule for completion. Precast concrete is a problem solver when time is of the essence because manufacturing happens offsite and weather plays no role in the erection schedule.

Learn More

University of Rhode Island Hillside Hall replaced outdated housing that deterred prospective students with a precast concrete five-story 429 bed housing unit with nine foot ceilings, two wings connected by a glass bridge and an open, airy campus view. Some of the design factors that made precast concrete the building material of choice included thermal efficiency, fire resistance, design flexibility and adaptability for the future and moisture/mold resistance.

Learn More

Worcester Polytechnic Institute Foisie Innovation Studio and Residence is a five story, mixed use academic and residential structure with customized precast components. The bottom two floors constitute the state-of-the-art Innovation Studio which is focused on STEM related activities and collaborative work. The flexible workspace includes labs and high tech classroom space and was built on an active campus with minimal area for staging. The total time necessary for panel erection was a mere 15 days.

Learn More

As the trend toward modernizing higher education campuses continues and budgets are stretched to their limits, precast concrete offers designers the options they need to create safe, aesthetically pleasing, high performing structures with the longevity to house generations of students for decades to come.

To learn more about Higher Education applications, request a learn@lunch program by contacting PCI Northeast.