Intro

Intro

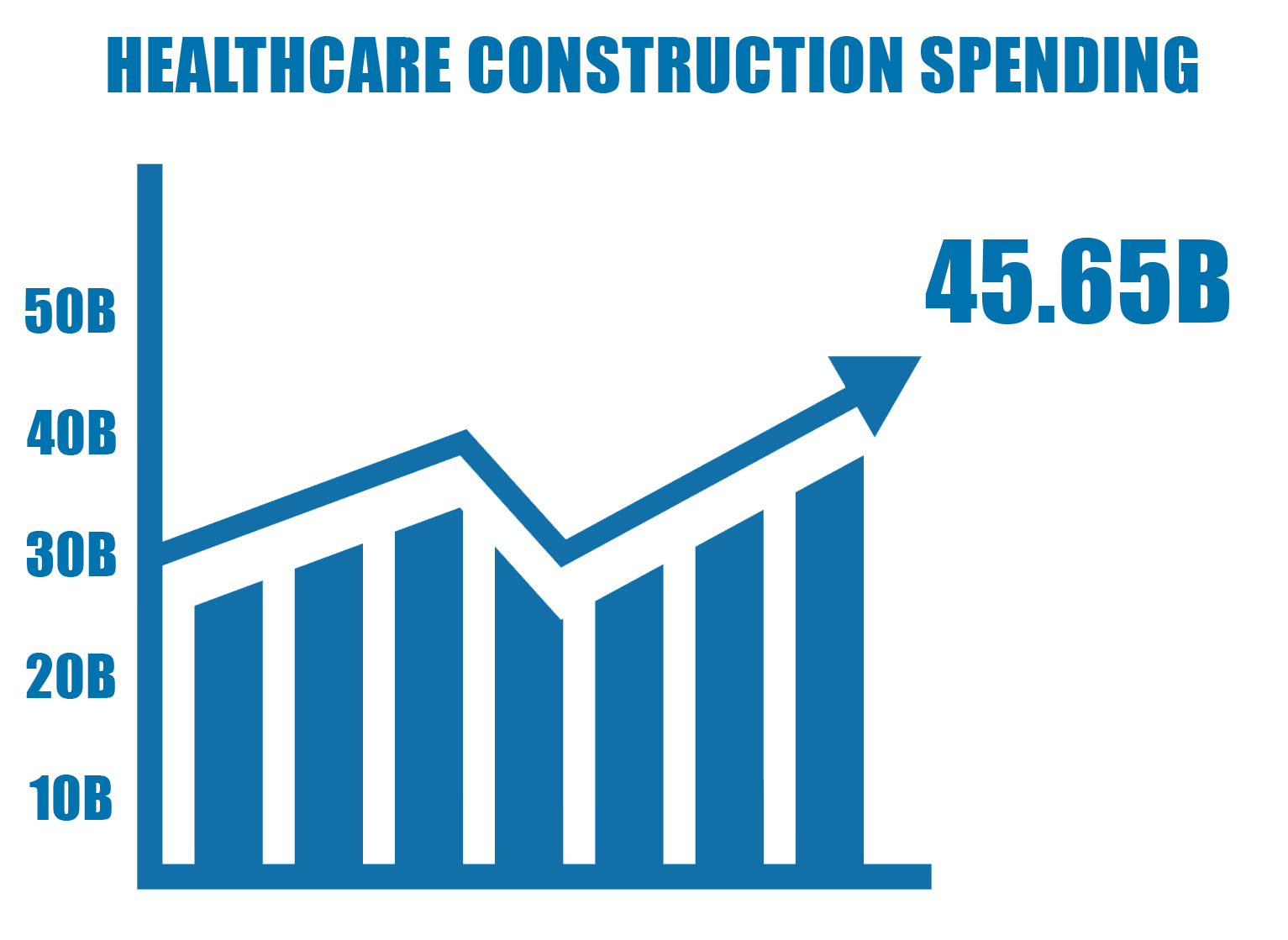

Precast concrete protects the valuable and the vulnerable. That’s why precast is a wise choice as a building material for hospitals and healthcare related structures. Healthcare construction in the US has been on a consistent incline and stands at 45.65B USD as of March 2020. When the goal is the creation of safe, sustainable, flexible and cost efficient structures...precast concrete building products rise to the occasion.

Why There is a Need

With an estimated 73 million baby boomers in the US, a spotlight is on the need for more and better healthcare facilities. As the aging demographic in our society is living longer, providing for their healthcare needs is an immediate concern. Across the US, communities are faced with aging/failing healthcare structures and/or inadequate facilities to meet the needs of the areas they serve.

The recent COVID crisis brought to the forefront the challenges hospitals are facing. For example, the inundation of COVID 19 patients in the Philadelphia area pushed Penn Med to face track part of their large scale Pavilion project to add additional emergency room space and inpatient rooms. The IPD (Integrated Project Delivery) team pulled together to meet the request in under two weeks using multi-trade prefabrication as a solution. Their masterful use of experience and teamwork is highlighted in this recent ENR Highlight.

What will the needs be

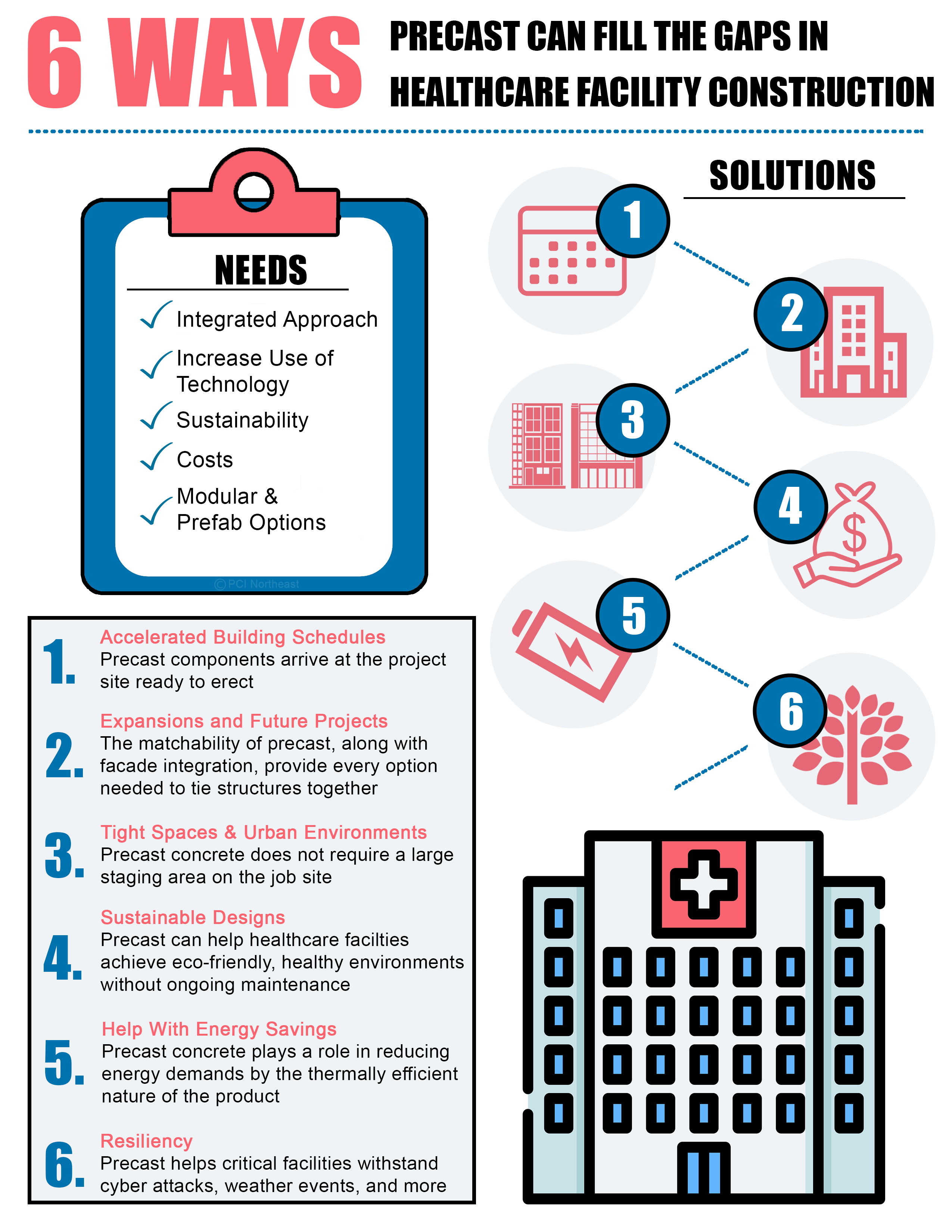

Funding for hospitals generally comes from a variety of resources including government held bonds and philanthropy. Those funds are stretched to the max to achieve the lofty goals of a healthcare construction project. With the 2020 respondents of the Healthcare Design’s A/E/C Survey revealing that 51% of their projects are tied to healthcare in one form or another, it’s clear that the aging population is driving this building trend. While attempting to meet the demand, these five key trends are being closely adhered to:

-

Integrated Approach: whether it’s a hospital, a school or a community building, flexibility is the name of the game with regard to building design. Planning for today with an eye on tomorrow helps designers create spaces that are adaptable, flexible and able to meet future needs. A key benefit of precast concrete is its ability to be reimagined and reworked.

-

Increase Use of Technology: Hospitals use technology in essentially every aspect of patient care. From data collection and medical records to high tech diagnostic equipment, creating spaces that dovetail with technological needs is what precast building systems do with ease. Precast concrete provides seismic/blast resistance and minimizes vibration and sound intrusion.

-

Sustainability: Hospitals use a vast amount of energy and resources to function, making precast concrete an excellent building material choice. The inherent thermal efficiency of concrete provides continual cost savings and long-term value.

-

Costs: Using prefabrication,precast concrete building products provide substantial savings due to the repetitive nature of the process and the decreased need for manpower.

-

Modular & Prefabrication Options: The very nature of precast products makes it beautifully suited for future growth and expansion. The ability of precast to match and multiply existing space to yield a seamless structure makes future additions easier to design.

How Precast Can Fill the Gaps

- Accelerated Building Schedules: With the arrival of precast components to the project site ready to erect, the building schedule is accelerated. In the case of healthcare facilities, by the time the project is funded and ground is broken, the completion can’t come fast enough as the need has already been there for quite some time.

- Expansions and Future Projects: Oftentimes, healthcare facilities are built on a campus type design where buildings match or favor one another to give a cohesive appearance. The matchability of precast, along with facade integration, color and texture options and accents such as brick provide every option needed to tie structures together aesthetically.

- Tight Spaces & Urban Environments: Hospitals are generally constructed in areas that make them easily accessible to the community they serve. The location is often in an urban area or “in town” where space constraints pose construction challenges. Precast concrete building components are perfectly suited to the challenge as they are delivered “just in time” to erect and do not require a large staging area on the job site. For additional information visit www.pcigulfsouth.org under the BLOG tab to read about constructing precast structures in tight spaces.

- Sustainable Design: The concept of the “Green Hospital” has evolved due to the excessive consumption of resources by healthcare facilities. With the goal of reducing energy consumption and creating an eco-friendly healthy environment, designers have adopted a more socially responsible approach to healthcare projects. Precast concrete building systems do not require the level of ongoing maintenance associated with other common materials such as wood. The weather resistant, durable nature of the product handles harsh conditions and maintains a like new appearance for decades resulting in significant cost savings.

- Help With Energy Savings: The 24/7 nature of hospitals along with large square footage and vast amounts of energy consumed by equipment make hospitals huge consumers of energy. Precast concrete plays a role in reducing energy demands by the thermally efficient nature of the product. Annual Heating and cooling costs, as well as initial HVAC system requirements, are significantly less than that of competing building materials

- Resiliency : Hospitals and other healthcare facilities are considered critical infrastructure for our nation. They need to be able to resist cyber attacks, weather events, and more while staying operational. Precast helps provide protection from these types of outside events and keep occupants safe on the inside. For example, the 2020 Design Award winning Mount Sinai Medical Center Skolnick Surgical Tower used precast panels to achieve both protection from hurricane-force winds and the aesthetic vision of the client.

Read why offsite construction practices work well for healthcare related construction projects.